- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

PP GF20

XINYITE

PP GF20, or Polypropylene with 20% glass fiber reinforcement, is a type of composite material commonly used in various industries for its enhanced strength and stiffness properties compared to standard polypropylene.

The addition of glass fibers to polypropylene improves its tensile strength, impact resistance, and dimensional stability. This makes PP GF20 suitable for applications that require high strength and rigidity, such as automotive components, consumer goods, electrical housings, and industrial parts.

Some of the key benefits of PP GF20 include:

1. High strength: The glass fibers embedded in the polypropylene matrix provide excellent strength, allowing it to withstand higher loads and stresses.

2. Stiffness: The glass fibers enhance the stiffness of the polypropylene, resulting in improved dimensional stability and reduced deformation under load.

3. Impact resistance: PP GF20 exhibits higher impact resistance compared to standard polypropylene, making it more suitable for applications that require good resistance to impacts or shocks.

PP GF20, or Polypropylene with 20% glass fiber reinforcement, is a type of composite material commonly used in various industries for its enhanced strength and stiffness properties compared to standard polypropylene.

The addition of glass fibers to polypropylene improves its tensile strength, impact resistance, and dimensional stability. This makes PP GF20 suitable for applications that require high strength and rigidity, such as automotive components, consumer goods, electrical housings, and industrial parts.

Some of the key benefits of PP GF20 include:

1. High strength: The glass fibers embedded in the polypropylene matrix provide excellent strength, allowing it to withstand higher loads and stresses.

2. Stiffness: The glass fibers enhance the stiffness of the polypropylene, resulting in improved dimensional stability and reduced deformation under load.

3. Impact resistance: PP GF20 exhibits higher impact resistance compared to standard polypropylene, making it more suitable for applications that require good resistance to impacts or shocks.

PROPERTIES | Units | METHOD | PP GF20 | |||

Tensile Strength | Mpa | ISO527 | 70 | |||

Mold shrinkage | % | ISO2257 | 0.6-0.8 | |||

Flexural Strength | Mpa | ISO178 | 90 | |||

Flextural Modulus | Mpa | ISO178 | 4500 | |||

Notched IZOD Impact at 23℃ | KJ/㎡ | ISO180 | 9 | |||

Density | g/cm3 | ISO1183 | 1.05 | |||

Flammability | - | UL94 | HB | |||

Melt Flow Index | g/10min | ISO1133 | / | |||

Heat deflection temperature (0.45MPA) | ℃ | ISO75 | 150 | |||

PROPERTIES | Units | METHOD | PP GF20 | |||

Tensile Strength | Mpa | ISO527 | 70 | |||

Mold shrinkage | % | ISO2257 | 0.6-0.8 | |||

Flexural Strength | Mpa | ISO178 | 90 | |||

Flextural Modulus | Mpa | ISO178 | 4500 | |||

Notched IZOD Impact at 23℃ | KJ/㎡ | ISO180 | 9 | |||

Density | g/cm3 | ISO1183 | 1.05 | |||

Flammability | - | UL94 | HB | |||

Melt Flow Index | g/10min | ISO1133 | / | |||

Heat deflection temperature (0.45MPA) | ℃ | ISO75 | 150 | |||

|  |  |

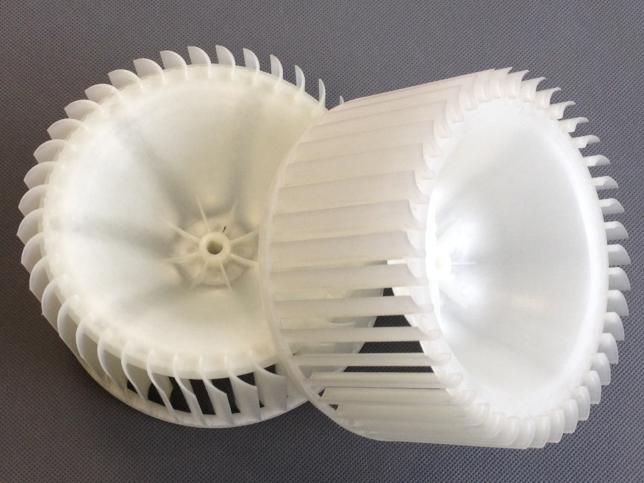

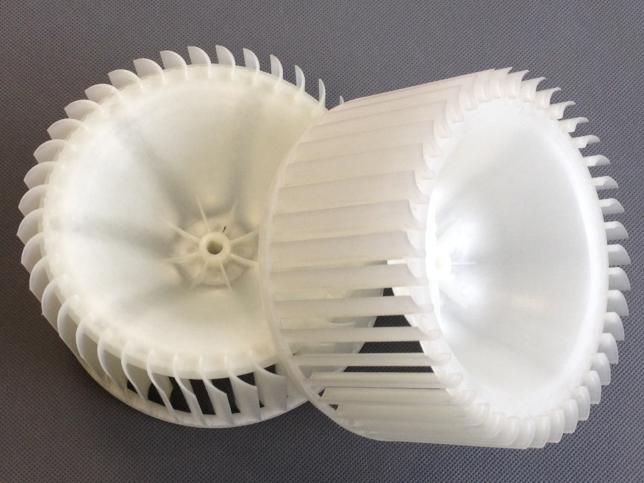

Chair accessories | Automotive wind wheel | Household appliances |

|  |  |

Chair accessories | Automotive wind wheel | Household appliances |