- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

PP GF15

XINYITE

This compounding PP material improves mechanical properties compared to pure polypropylene.

Here are some characteristics and advantages of PP GF15 material:

Strength and Stiffness: The addition of glass fiber enhances the strength and stiffness of polypropylene, making it suitable for applications where structural integrity is important.

Impact Resistance: The composite material tends to have improved impact resistance compared to unfilled polypropylene.

Dimensional Stability: Glass fiber reinforcement can contribute to better dimensional stability, reducing warping or deformation of the material.

Heat Resistance: The presence of glass fibers can enhance the heat resistance of the material, allowing it to withstand higher temperatures compared to pure polypropylene.

Weight Reduction: Despite the addition of glass fiber, PP GF15 is generally lighter than many metals, making it useful in applications where weight is a critical factor.

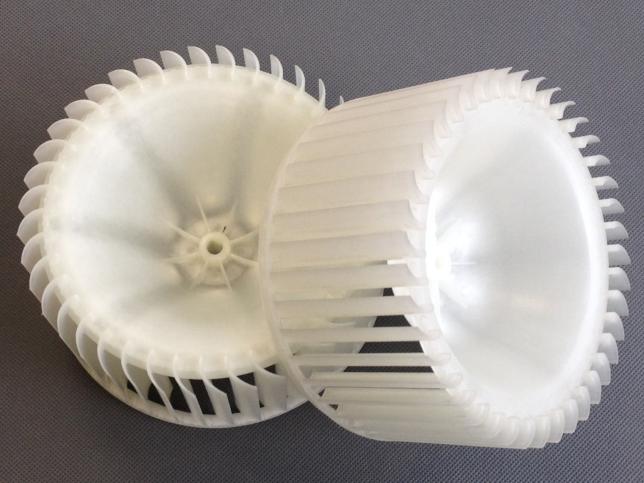

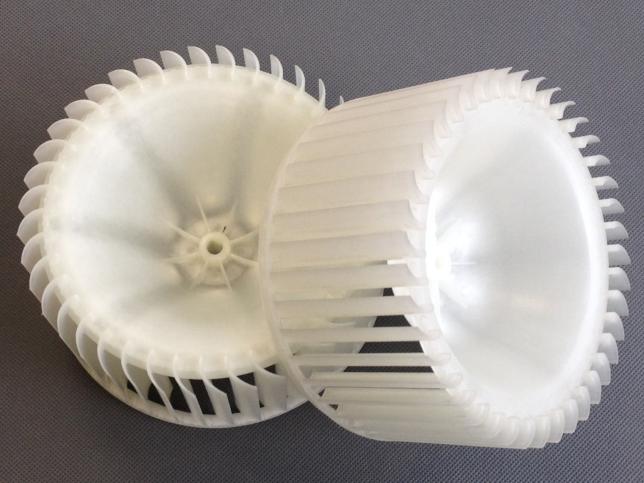

Applications: PP GF15 is commonly used in automotive parts such as engine covers, door panels, and interior trims. It is also used in electrical connectors, power tools, and various household appliances.

This compounding PP material improves mechanical properties compared to pure polypropylene.

Here are some characteristics and advantages of PP GF15 material:

Strength and Stiffness: The addition of glass fiber enhances the strength and stiffness of polypropylene, making it suitable for applications where structural integrity is important.

Impact Resistance: The composite material tends to have improved impact resistance compared to unfilled polypropylene.

Dimensional Stability: Glass fiber reinforcement can contribute to better dimensional stability, reducing warping or deformation of the material.

Heat Resistance: The presence of glass fibers can enhance the heat resistance of the material, allowing it to withstand higher temperatures compared to pure polypropylene.

Weight Reduction: Despite the addition of glass fiber, PP GF15 is generally lighter than many metals, making it useful in applications where weight is a critical factor.

Applications: PP GF15 is commonly used in automotive parts such as engine covers, door panels, and interior trims. It is also used in electrical connectors, power tools, and various household appliances.

PROPERTIES | Units | METHOD | PP GF15 | |||

Tensile Strength | Mpa | ISO527 | 60 | |||

Mold shrinkage | % | ISO2257 | 0.7-0.9 | |||

Flexural Strength | Mpa | ISO178 | 70 | |||

Flextural Modulus | Mpa | ISO178 | 3000 | |||

Notched IZOD Impact at 23℃ | KJ/㎡ | ISO180 | 7.5 | |||

Density | g/cm3 | ISO1183 | 1.02 | |||

Flammability | - | UL94 | HB | |||

Melt Flow Index | g/10min | ISO1133 | / | |||

Heat deflection temperature (0.45MPA) | ℃ | ISO75 | 150 | |||

PROPERTIES | Units | METHOD | PP GF15 | |||

Tensile Strength | Mpa | ISO527 | 60 | |||

Mold shrinkage | % | ISO2257 | 0.7-0.9 | |||

Flexural Strength | Mpa | ISO178 | 70 | |||

Flextural Modulus | Mpa | ISO178 | 3000 | |||

Notched IZOD Impact at 23℃ | KJ/㎡ | ISO180 | 7.5 | |||

Density | g/cm3 | ISO1183 | 1.02 | |||

Flammability | - | UL94 | HB | |||

Melt Flow Index | g/10min | ISO1133 | / | |||

Heat deflection temperature (0.45MPA) | ℃ | ISO75 | 150 | |||

|  |  |

| Chair accessories | Automotive wind wheel | household appliances |

|  |  |

| Chair accessories | Automotive wind wheel | household appliances |